2 shot molding (sometimes referred to as dual injection or overmolding) is the process of injecting two different materials into a single mold. This enables enhanced design options and functionality.

Although the process is relatively simple to understand, it can be difficult to master. The smallest mistake can be costly, especially in high-volume production scenarios.

1. Stronger bond

The two shot process allows for a stronger bond than a product made using separate molding processes. This makes for a more durable product and prevents the need to replace the part in the future due to damage or wear.

The chemistry of the materials used is carefully considered before implementing this technique to ensure that they bind well together and form a solid molecular adhesion. In the event that the adhesive quality of the two compounds isn’t ideal, fixes can be incorporated into the mold design, such as undercuts or grooves, to improve the adhesion.

This method can also be used to create multicolored products and is far more effective than painting which may lose its integrity over time. It’s often used to manufacture plastic handles, multicolor knobs, and hinges as well as air conditioning seals, soft toothbrush handles, and caps.

2. More flexibility

The ability to integrate two different plastic resins in one injection molding cycle makes this process very versatile. Product designers can utilize the structural properties of a hard material with the soft and appealing nature of a different material, improving product functionality and marketplace value.

This process, also known as dual-shot, double-molding or multi-shot molding, is highly precise because there’s no need to remove the part for the second injection. As long as the design is properly engineered to account for thermal effects and other variables, the final product will be exactly as designed without additional assembly and secondary operations.

Because of the higher level of technical expertise and attention to detail required in this production process, it’s important to partner with a supplier with an excellent quality scorecard and defined processes to mitigate issues such as flash and short-shots. An experienced supplier can also provide design assistance to help engineer value into your final product.

3. Lower costs

This process allows manufacturers to combine a load-bearing structural base and a soft material or color that enhances the look of your final product. This eliminates the need for additional machining steps, such as welding or gluing. It also reduces production costs by combining multiple machine cycles into one.

This type of molding is often used for buttons and switches, handles and grips on appliances and devices, as well as toothbrush handles. The process creates a durable, strong bond between the hard plastic base and the more appealing soft-touch materials.

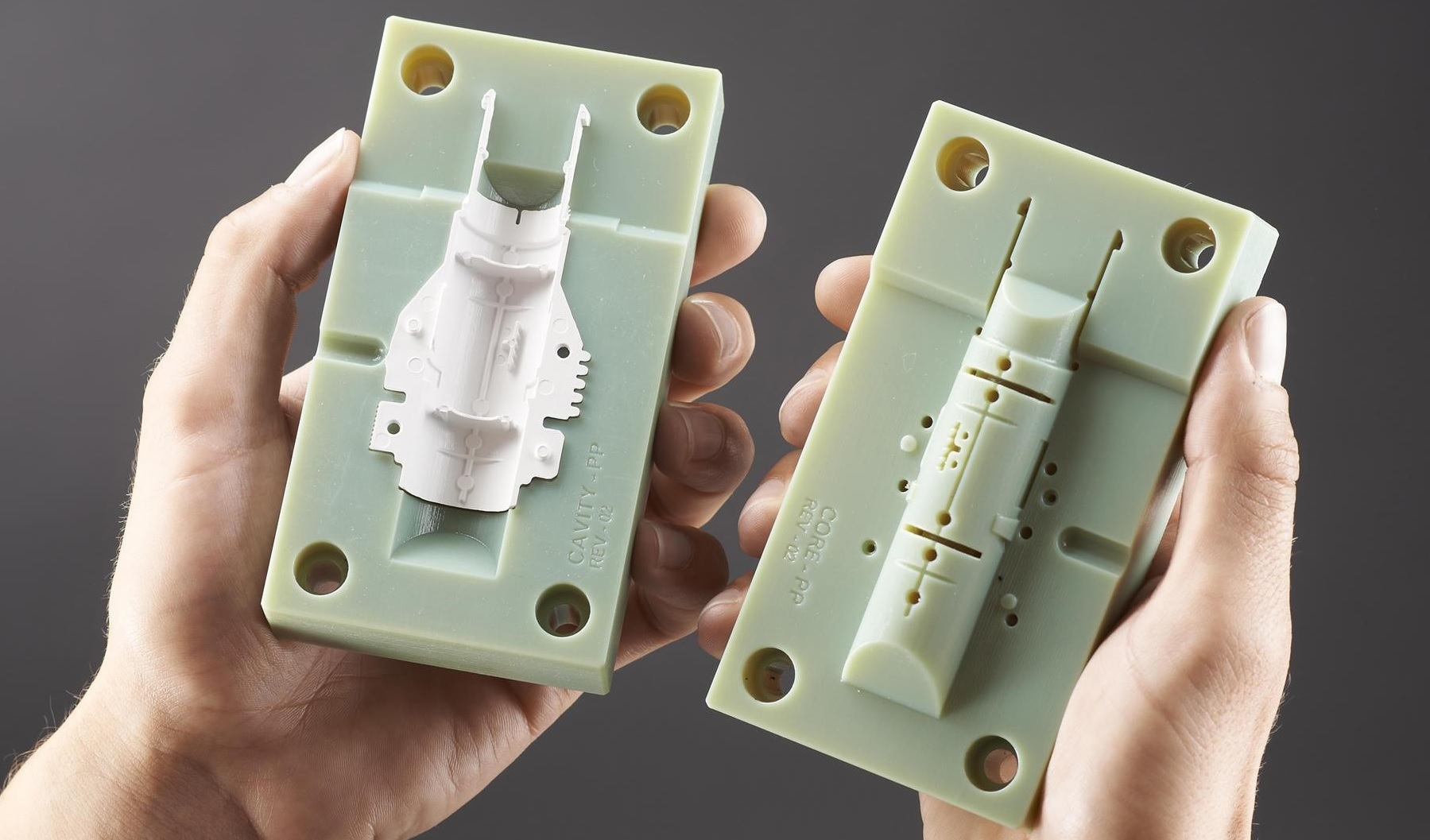

The two shot molding process requires a different set of tools and machinery to accommodate the injection of separate shots. A special feed hopper channels the two shots to their respective injection units on a rotating mold mechanism.

4. Durability

The two-shot injection molding process allows multiple parts to be molded in one cycle. This is far more efficient than having two separate injection molding processes making the same part, and saves machining costs.

This method is used to produce toothbrush handles, buttons and switches, and other plastic equipment that require a combination of hard and soft materials. It also improves ergonomics by allowing soft-touch surfaces to be added to hard substrates, a major benefit for tools and medical devices.

In addition, the process can provide more durable products, as it reduces the number of crevices where sub-parts interface. This is particularly important when working with medical and military equipment where hygiene is key. Colors can be incorporated into the design, eliminating the need for a painting process that may wear off over time.

5. Design flexibility

Two shot molding allows for a wide variety of design possibilities. The first plastic resin is molded and then a second shot of material can be injected in, through, or around certain parts of the first molded part to create more functionality, enhancing product value and appeal.

For example, the process could mold a hard plastic base with a soft rubber overmold for comfort or a firm grip. This eliminates secondary assembly operations, such as gluing and insert molding, and improves product quality and reliability.

Because of the complexity involved, 2 shot injection molding requires a high level of technical expertise and attention to detail. Look for a supplier with a strong track record and defined processes to mitigate potential issues such as flash, flow lines, and short-shots.