A high pressure fire pump delivers more power and gallons per minute. It can also run dual lines easily with less stress on the fire pump and nozzles.

When choosing a fire pump, look at the horsepower curve on the factory-certified test report. It should peak and then fall. A motor that continues to rise could be undersized and in violation of NFPA requirements.

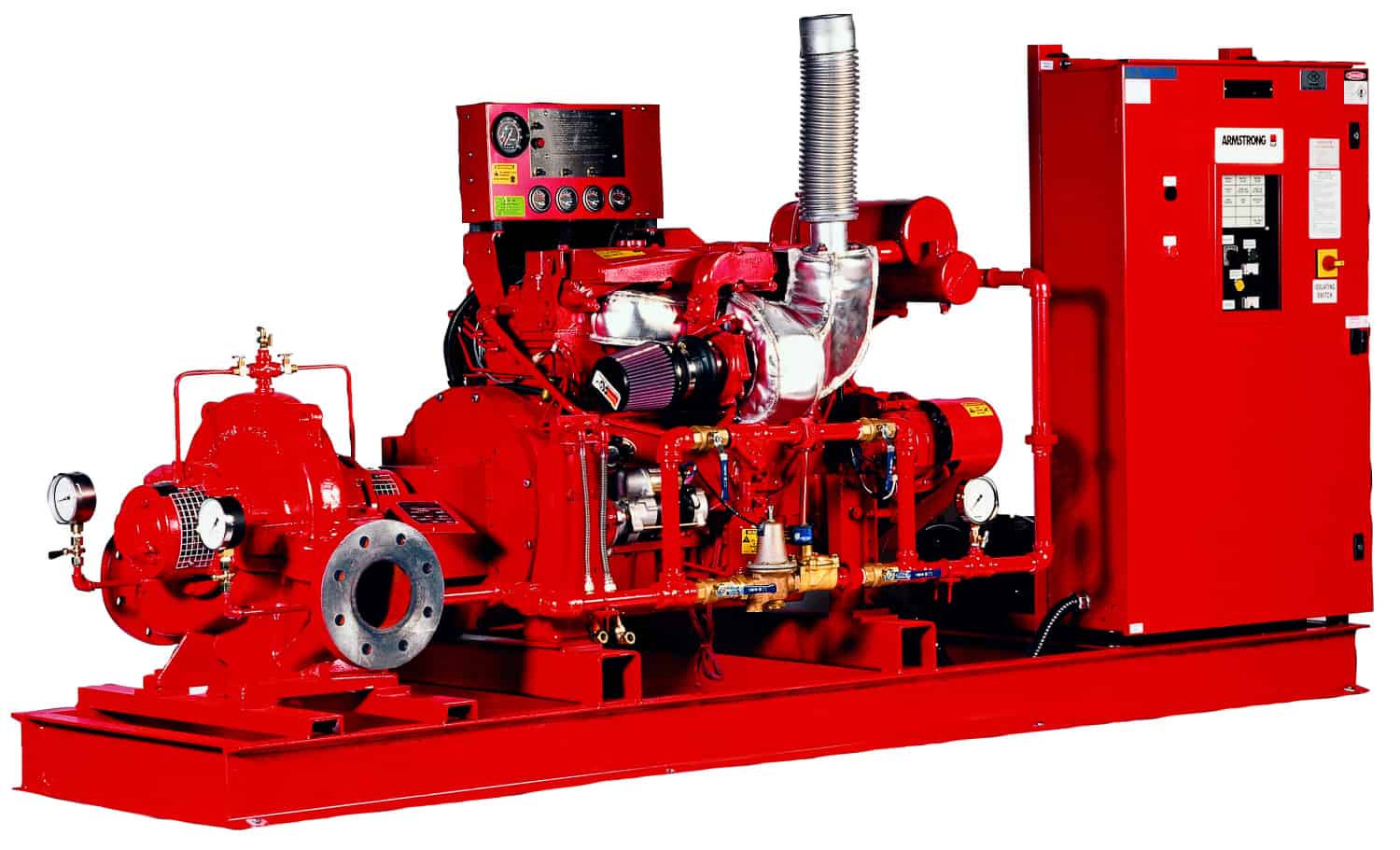

UL and FM Approved

When selecting a fire pump, it is essential to consider the pressure that it can generate. This is important because the fire pump cannot create more pressure than the system components can handle, as this could lead to a catastrophic failure. Ideally, the fire pump should be capable of generating at least a rated net pressure of 40 to 250 psi at its rated flow.

In addition, the fire pump should be water-sealed. This can be achieved by using a stuffing box that is equipped with compression packing and water-sealed to a minimum suction pressure of 30 psi. It is also recommended that the pump have a lantern ring and glands to apply uniform pressure.

UL listed and FM approved fire pumps are widely used in most industries because they comply with the National Fire Protection Association (NFPA) codes and standards – especially NFPA 20. These fire pumps have been inspected and tested to ensure that they are safe and reliable. Moreover, they are very easy to install and use.

Moreover, the mechanical design of UL-listed fire pumps must comply with the requirements of NFPA 20, as well as the specific requirements of NFPA 448 – Centrifugal Stationary Pumps for Fire-Protection Service. The design must also comply with the FM standards for volute-style fire pumps. Ideally, the mechanical design of a fire pump should have a balanced G6.3 balance quality.

Powerful

High pressure fire pumps are able to deliver water at a very high volume and force. They are designed to help control the fire until firefighters can arrive to extinguish it altogether. They can do this by spraying water from a hose up to 75 meters in height.

It is important to know how much pressure a fire pump will produce at different flow conditions so that it can be properly sized for your system. This can be done by looking at the manufacturer’s performance curve for the model you want to purchase. This curve will plot the flow on the “x” axis and the net pressure produced by the pump on the “y” axis. It will also include the minimum requirements for churn and maximum flow, as well as a 150% required duty point.

The power requirement for a fire pump is based on the pressure it will be able to generate at its lowest rated flow, and the friction losses experienced between the water supply source and the discharge flange of the fire pump. Using these factors, it is possible to determine the size of electric motor and diesel engine required to achieve the required pressure.

Jockey pumps, small, high-pressure pumps used for maintaining pressure in a fire pump, are typically electrically powered and require one to ten horsepower. They are especially useful for systems that need to operate over long hose lays and overcome large elevation changes in rugged wildland fire operations.

Lightweight

Fire pumps need to be powerful enough to provide sufficient pressure for a system, but they also need to be lightweight and portable. Otherwise, they will be difficult to maneuver in the field and could cause damage to components if they create too much pressure. This is why selecting the correct fire pump is so important.

Firstly, look at the maximum head specification – this refers to how high up you can pump water at full capacity. Typically, a higher maximum head means more pressure at the top but less flow rate down to the ground level. Secondly, look at the maximum pressure in PSI – this will determine how far you can pump water uphill and overcome pressure losses.

Finally, look at how easy the pump is to start – choose a model that has a recoil or electric starter to ensure reliable operation. Also, choose a durable engine that can withstand the pressure of the pump and its operation for the long term.

A good example of a light and portable fire pump is the Rosenbauer UHPS Ultra High Pressure System, which has been designed for fast attack engines and is easily installed in rescue vehicles. It can be used in conjunction with the appropriate nozzles and fire hoses to deliver water under high pressure to help combat wildfires.

Easy to Operate

When looking at the specifications of any fire pump, you will see two acronyms that are vital to understand – PSI and GPM. These stand for pressure per square inch and gallons per minute respectively. The pressure is important as it relates to how much force the water is being delivered with and the GPM indicates how many gallons of water the pump is capable of discharging in a certain amount of time.

There are many different options available to fire departments when selecting a fire pump for their vehicle. The most basic is a single-stage centrifugal fire pump or a two-stage series/parallel fire pump. Both of these are able to produce a high-pressure water flow, but the one that will be most useful to the department depends on the type of vehicle it is being installed in and the application for which it will be used.

A designer should always use the manufacturer’s performance curve to determine the appropriate size of fire pump for a given situation. This curve will provide the net pressure (in psi or bar) that can be achieved at all of the various flows between churn and the demand flow of the fire protection system.

In addition to determining the correct size of fire pump, the designer should also take into account whether or not they will be using an in-line or split-case fire pump. In-line pumps are the most common and have their driver mounted above the pump, whereas split-case pumps have their driver below the pump. While in-line fire pumps are typically less expensive and require less space, they can be more difficult to repair when compared to split-case units.